Baja SAE

Chassis Engineering (2024)

Summary

For the 2024 season, I designed the chassis for the Blue Jay Racing 20XT. I was also lead of the frame sub-team which includes the chassis, seat, body panels, floors, covers, and all miscellaneous equipment on the vehicle (fire extinguisher, brake light, etc.)

The chassis was an extremely fun challenge for me - I had the opportunity to work with nearly the entire 30+ person team on integration while also working through complex 3D sketches and weldments in SolidWorks. I leveraged Ansys structural analysis using inertial relief and static analysis to analyze the frame. The result was a chassis approximately 15% smaller and lighter than previous years.

R&D

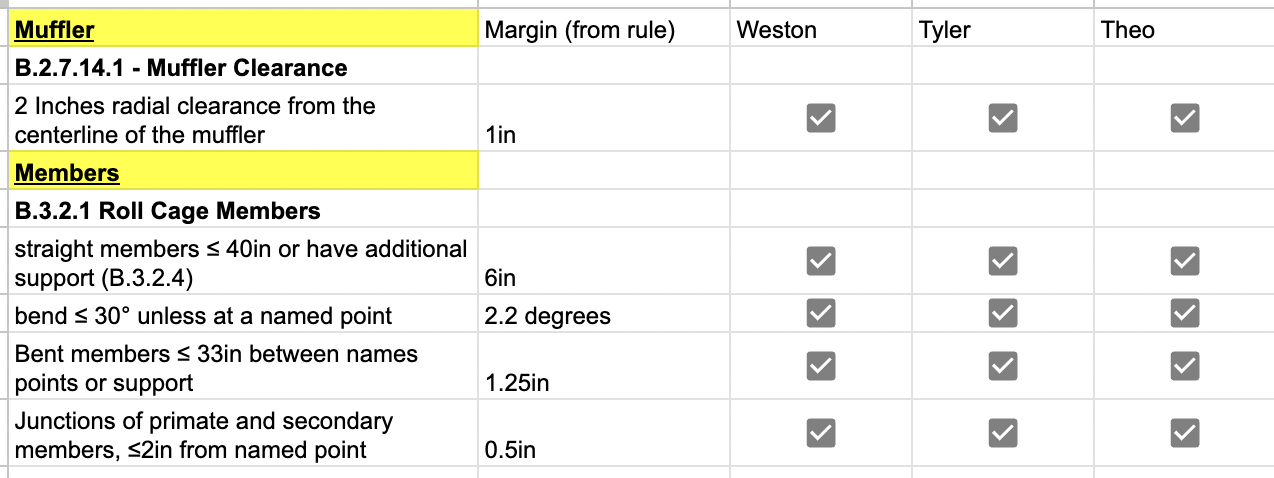

The Baja ruleset heavily restricts chassis geometry, material selection, and attachments. As such, the obvious first step in designing one is to become familiar with the rules. I created a spreadsheet to familiarize myself with them, as well as keep track of my quantifiable margins to the requirements. It also included columns for later on, when myself, the team captain, and the previous frame designer would go over these rules to ensure compliance.

Although the rules do heavily restrict geometry, there was still plenty of room for improvement over the previous years frame. For example, familiarity with the rules made it clear a handful of tubes could be removed (some were eventually returned in the analysis phase). However, the most dramatic change was driven by an ideology shift of the frame design. The frame was previously designed to the largest individual on the team. I elected to design the frame just to our primary driver, which allowed a dramatic downsize (and weight reduction) without a considerable change in design language.

Overlay of my frame (green) onto the previous frame (red)

Offset surfaces from helmet model to check driver clearances rule

Frame rules spreadsheet

Analysis

As a quick background, the frame is driven largely by suspension load cases (compressive and tensile forces through suspension tabs, and into the frame) as well as rollovers (forces directly applied to frame members).

Up until this point, every frame at JHU Baja was analyzed statically. Some number of points were selected as fixed supports, and load was applied to others. After creating results that were not intuitively reasonable, it was decided to change to an inertial relief model. This is still not completely ideal, as it does not perfectly represent the behavior of the car, nor the other contacts the car my have with the ground. An ideal model would include vehicle velocity, ground geometry (as well as stiffness and friction). This is a very difficult model to create, and was outside the scope of my abilities at the time. In retrospect, attaching many strain gauges to an old frame would have been the most informative test I could have done. Because the frame had a similar design language (mostly driven by suspension geometry) the margins seen from that data would likely be similar to those seen in my frame.

Analysis from steering rack loads

The wheel-force transducer we used to measure suspension loads

Manufacturing

The manufacturing of my frame revolved around a jig created from two large aluminum plates, 80-20 extrusion, and shaft collars. This has many advantages, but the most notable are: material is almost completely reusable every year, construction is very fast (just a mill required), and easy to modify (supports could be added and removed to balance rigidity with access at any level). One of my teammates did all the welding. I made a half-hearted attempt to learn to TIG weld before realizing it is incredibly difficult to do well. It made me gain a lot of respect for the process, and people who do it.

I also formulated a novel manufacturing method for creating holes within tube bends. (which was required due to new suspension requirements). Particularly, holes that were not orthogonal to the bend plane. A negative of the tube was 3D printed with dowel pins for datums, and the hole was created in a CNC mill using helical Interpolation (the drill in the image was used just to visually confirm the location).

Drilling difficult holes

Half-welded frame, still in jig

Testing

Explicit testing of the frame is financially difficult for our team. The monetary and time cost to create one is very significant, so we only ever felt comfortable taking it to about 50% of yield. This meant we could only (intentionally) do very controlled bench-top testing. The primary test I ran was aimed at verifying the material properties and joints used in my analysis. I attached weights to a shock attachment point of the chassis and measured deflection. I then evaluated an identical situation using my FEM.

The above test was a derivitive of a “torsional rigidity” test, which actually provides more useful info. Notably, it can help you understand how your chassis plays into suspension characteristics. In the Baja use case, the defelction seen in the chassis is insignificant compared to the ~13in of suspension travel. For this reason, I omitted the torsion part to make the test easier, while still providing all the information that was useful to our particular case.

Also under my leadership, the frame sub-team conducted a test to determine the best hydrophobic coating for use on various surfaces across the car. I didn’t do much of it myself, but thought I would include it for the sake of completeness (one of the coatings was used on the chasses).

Measuring deflection during testing

Hydrophobic coatings test

Knowledge Transfer

After completing what I would call my first “real” design cycle, I had a good retrospective on the entire process. To help the next designer along, I created three notable peices of documentation: two videos outlining the SolidWorks and Ansys skills and procedure to model and analyze the frame and a document covering most of everything not covered in the above videos. I’m particularly proud of the document which covered everying you read above in excellent detail, as well as everything from how to send files to the tube bending manufacturer, to the best angle grinder discs to remove mill scale before welding, and 20 or so pages in between. The document is also being updated every year, and now contains most of what someone would need to design a frame.

Finally, I acted as an advisor to the engineer who followed me. Although, I would consider that more of an expectation than a highlight.

Frame design document

A screenshot from my SolidWorks tutorial

Drivetrain Engineering (2025)

Summary

For the 2025 season, I led the development of the drivetrain for the 21XT vehicle. Under my leadership, we removed the engine mounting plate from the car, reducing hours of extremely valuable machine-time while also lowering the center-of-mass and weight of the car. I personally developed custom universal joints for the vehicle during this season.

My custom U-Joints allowed for 45+ degrees of misalignment. This extremely large misalignment was the primary reason for developing a custom version, as it allowed us to utilize novel suspension geometry. We previously used U-Joints with less than 35 degrees of misalignment, which significantly limited our options. 3D printed prototypes were used to verify theoretical misalignment.